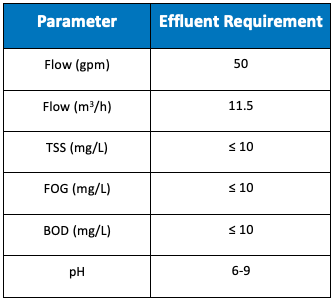

A leading company in the plant based oil and fats industry needs to discharge water from a new plant into the Gulf of Mexico. This new facility will generate over 100,000 GPD of wastewater with high levels of Total Suspended Solids (TSS), Fats, Oils, and Grease (FOG), and Biochemical Oxygen Demand (BOD) and needed a cost-effective solution that could meet the strictest of limits.

With the FRC turnkey solution, the client will recover commercially valuable byproduct and re-use water for their cooling towers.