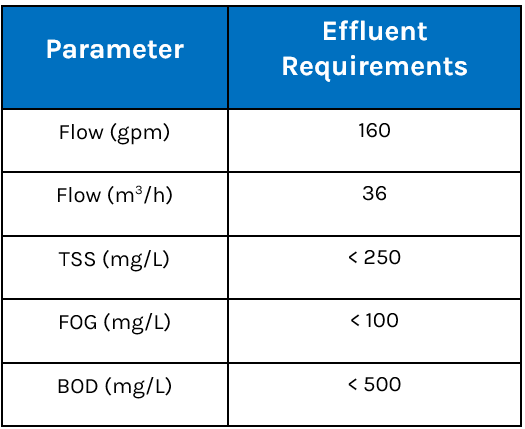

FRC’s client, the largest vertically integrated seafood company in North America, was building a greenfield plant that needed a wastewater treatment system capable of meeting city requirements. The site produces frozen seafood products in a variety of styles such breaded and glazed, as well as other pre-prepared foods. Their production process resulted in wastewater with high levels of Total Suspended Solids (TSS), Fats, Oils, and Grease (FOG) and Biological Oxygen Demand (BOD). FRC’s engineered team designed a complete turnkey wastewater treatment system to meet the customer’s needs.

Seafood Application: Turnkey Solution

Design Data

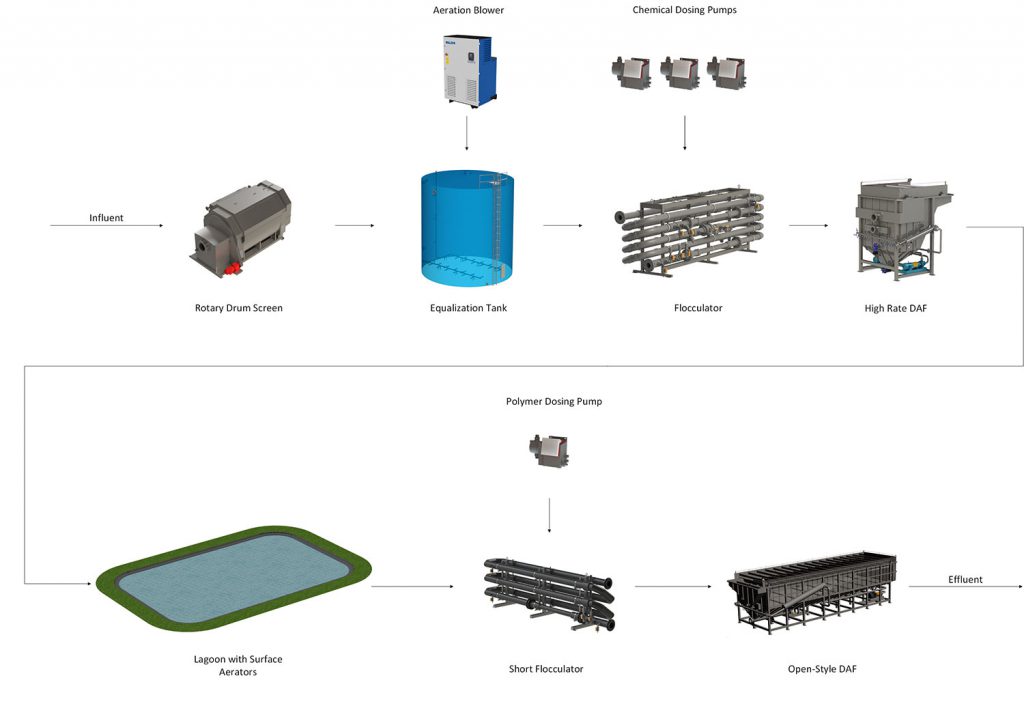

FRC Solution

- Rotary Drum Screen – Remove coarse solids such as small and large pieces of fish to protect the downstream equipment

- Equalization – Homogenize wastewater for consistent wastewater characteristics. Aeration mixing is provided to prevent anoxic conditions and formation of ammonia

- Primary Flocculator – Chemicals dosed to precipitate the colloidal solids

- Primary High-Rate DAF – Float the precipitated solids (TSS, FOG and any insoluble BOD). Removing TSS and any FOG is critical for biological treatment

- Biological Treatment – Removes the soluble BOD, creating a biomass that must be removed

- Secondary Flocculator – Short flocculator to precondition biomass with flocculant

- Secondary Open-Style DAF – Float the biomass for final effluent to discharge to city