Jar Testing

A FRC Systems jar test provides a simple and effective qualitative test in which we add various coagulant and/or flocculant chemicals to your wastewater samples in order to determine a combination that results in effective solids removal with dissolved air flotation (DAF) treatment. We also offer optional analytic testing for both treated and untreated samples, including Total Suspended Solids (TSS), Fats, Oils & Grease (FOG), Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), and many others.

Based on the jar test results, FRC can recommend the proper pretreatment chemicals to discuss with your chemical supplier. The coagulants will be selected based on the application, wastewater characteristics, and sludge disposal options.

FRC Jar Testing

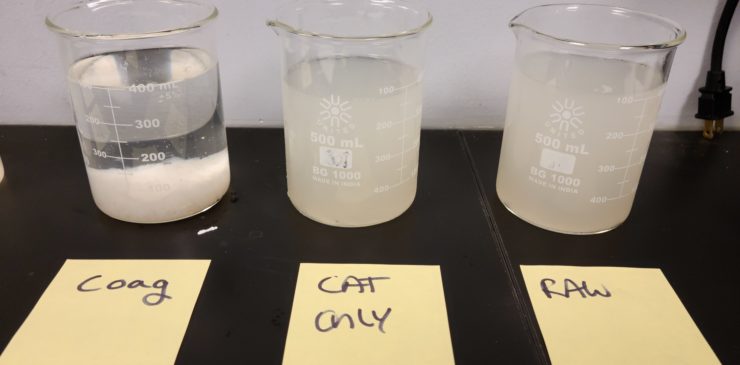

Coagulation

This is a purely chemical process which involves the destabilization of colloidal particles forming micro-flocs with a positive charge. We are determining how quickly micro-flocs can be formed to select the proper FRC product selection. During this step, we can determine a preliminary dosing recommendation.

Flocculation

The flocculant is a polymer that attracts the opposite charged micro flocs, and agglomerates the micro flocs into larger “macro flocs”. This is done in order to achieve a size suitable for separation in the flotation cell. Polymers can be an anionic, cationic, or nonionic.

DAF Simulation

In this step we generate whitewater by pressurizing water in a dedicated vessel. We inject the generated whitewater into the waste water sample to observe how the dissolved air interacts with the previously formed macro-flocs.

Sludge Testing

We also offer sludge testing which involves applying pressure to evaluate the behavior of the sludge. This allows FRC to recommend the proper dewatering technology.