MBBR

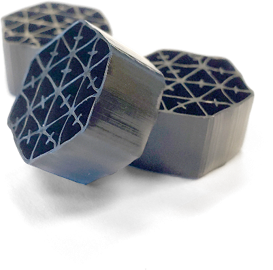

FRC Engineers use biological treatment primarily to remove biodegradable contaminants in wastewater. The FRC Moving Bed Biofilm Reactor (MBBR) biological treatment method uses small pieces of carrier material which are designed to maximize surface area and promote biomass growth. The MBBR tank is filled with these carriers, typically 30-70% by volume. The tank is aerated to feed the biomass and circulate the carriers throughout the tank, hence the ‘moving bed’ description. The bacteria grow on the carriers and consume contaminants, converting them to more biomass which can then leave the tank and be separated with a Dissolved Air Flotation (DAF) system or another form of clarification.

FRC uses MBBR technology to remove Biological Oxygen Demand (BOD) from wastewater, as well as to remove nitrogen and nitrogen-based compounds, phosphorous, and some forms of chemical oxygen demand (COD). MBBR systems are applicable in a wide variety of industrial and municipal applications.

MBBR Features

Completely Automated Systems

Since there is no balancing or additional processing required for the Return Activated Sludge (RAS), no additional intervention is required. This means no Mixed Liquid Suspended Solids (MLSS) analysis is needed. The FRC MBBR process gives a complete hands-off approach for the wastewater treatment system.

High Biomass Concentration

The carrier media in the MBBR allows for a much higher biomass concentration than in a typical tank without media. This means that the system can be installed with a much smaller tank than a conventional biological system.

Design Flexibility

An existing MBBR system can be upgraded for plant expansion by simply adding more media to the existing tank and introducing additional oxygen. This eliminates the need for a new tank.

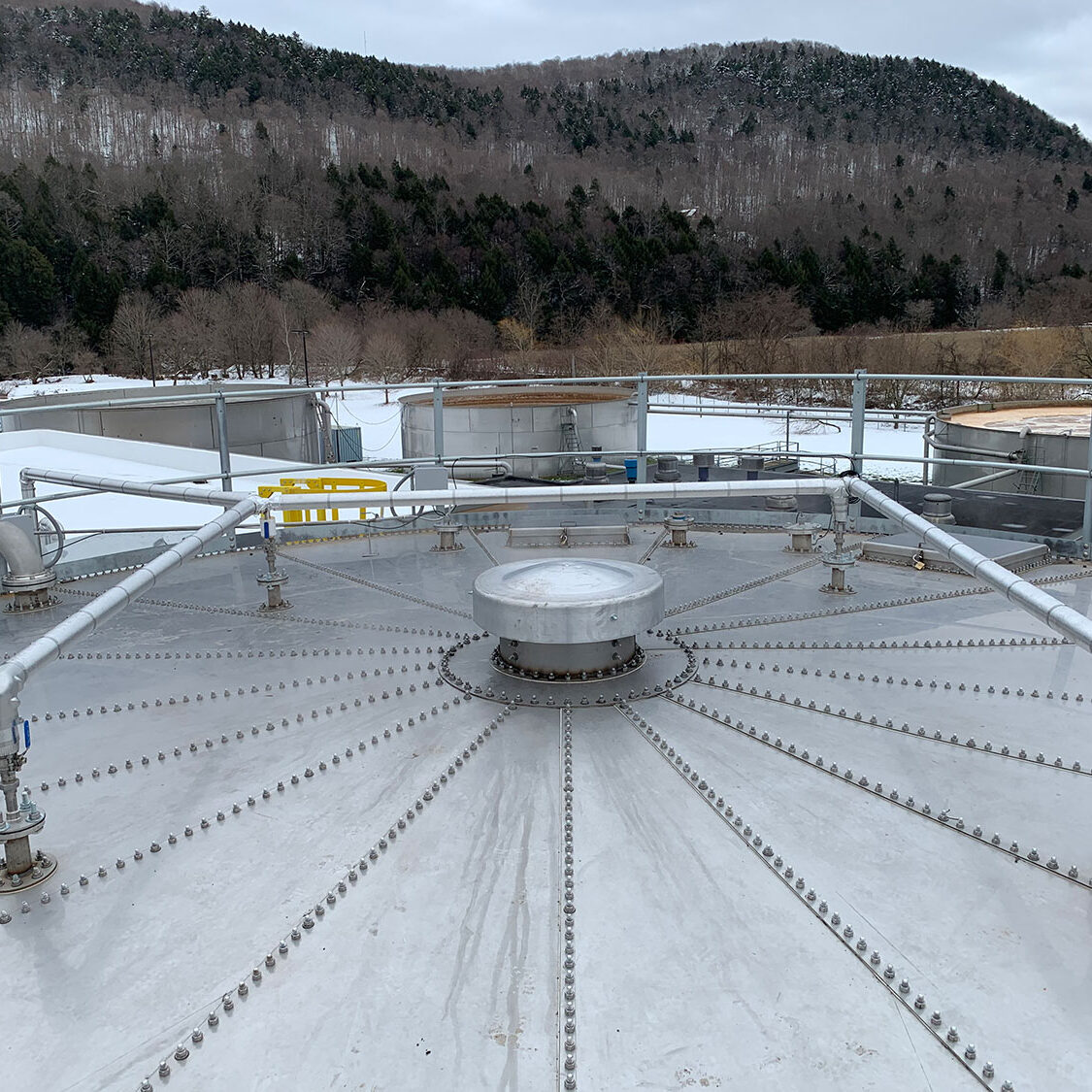

Material of Construction

FRC’s standard MBBR systems are installed in above-ground tanks made of durable stainless steel. We can also install the system in your existing concrete basin if it is sufficient in size.