Dissolved Air Flotation (DAF) Systems

Overview

DAF Solutions for Industrial and Municipal Wastewater

FRC Dissolved Air Flotation (DAF) systems remove TSS, FOG, BOD & COD from industrial and municipal wastewater. Durable stainless-steel designs with high-rate, compact, and open-tank options deliver reliable separation and compliance.

FRC Dissolved Air Flotation (DAF) systems remove Total Suspended Solids (TSS), Fats, Oils & Grease (FOG), Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), and other contaminants. Available in high-rate, compact, and open-tank designs, FRC units deliver dependable separation for industrial and municipal wastewater. With stainless-steel construction, plug-and-play setup, and automated controls, our DAF systems ensure compliance while reducing costs.

DAF works by dissolving air into a pressurized recycle stream of clarified effluent. When released into the tank, microbubbles attach to solids, oils, and grease, lifting them to the surface for skimming. Clarified effluent exits for reuse or discharge. FRC high rate designs use plate packs, to boost separation efficiency, cut energy use, and shrink system footprint.

FRC’s PCL-Series DAF removes solids, oils, and FOG using high-rate flotation, crossflow plate packs, and in-tank sludge thickening for high-capacity wastewater applications.

The PCCS-Series is a space-saving DAF system that can ship in a 20-ft ISO container—ideal for remote, temporary, or small-scale wastewater applications.

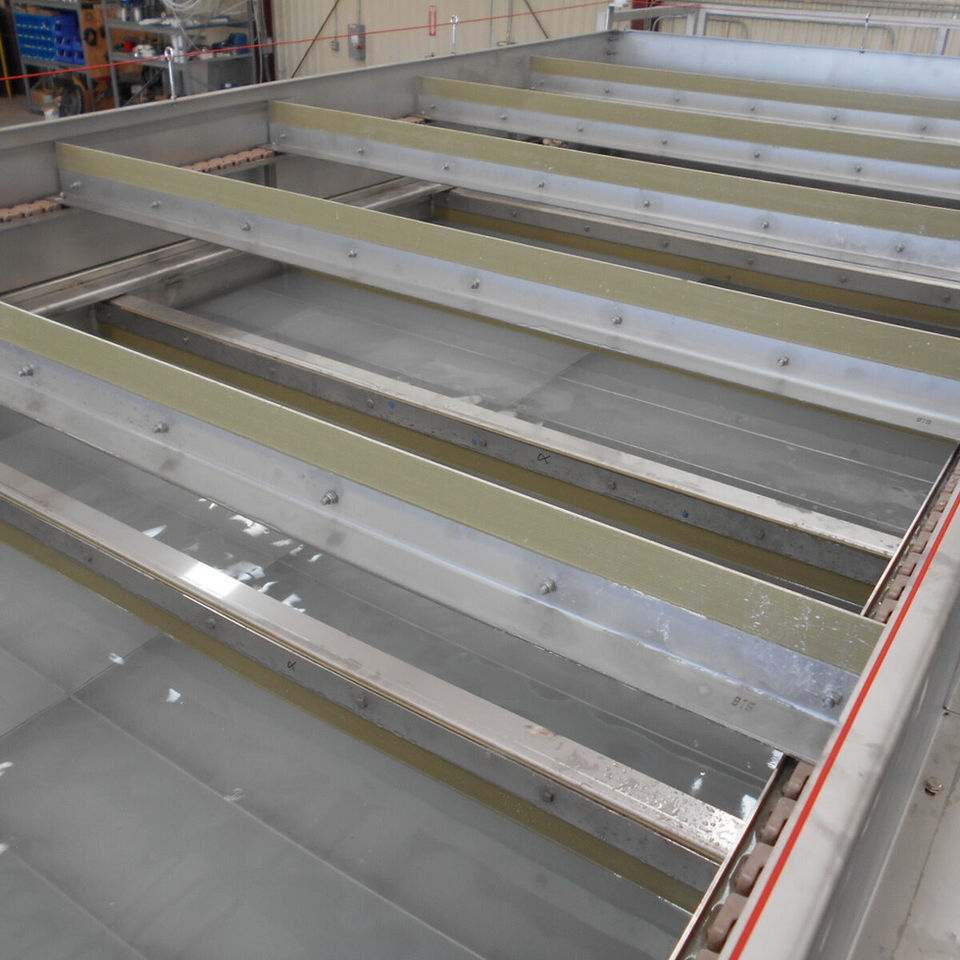

FRC’s PWL-Series DAF handles heavy solids with a counter-current skimmer, large flotation surface, and sludge dewatering grid for efficient solids removal.

Key Features

High-efficiency removal of TSS, FOG, BOD, and COD

Multiple configurations: high-rate, compact, and open-tank designs

Non-proprietary pumps with angled air dissolving tubes

Sludge dewatering grid option for drier, denser sludge

Corrosion-resistant stainless-steel construction with alloy options

Fully customizable system configuration including skids, catwalks, and controls

Specifications

Flow Rates: Up to 2,000+ GPM

Free Area: 5 – 500+ sq ft

Effective Area: 35 – 3,100+ sq ft

Construction: Stainless steel (304, 316, duplex, or custom alloys)

Applications

Food & Beverage wastewater treatment (meat, poultry, dairy, breweries)

Oil & Gas, petrochemical, and refinery effluent treatment

Pulp & Paper and chemical manufacturing facilities

Municipal wastewater pretreatment and sludge thickening

Mining, landfill leachate, and renewable fuels industries

Any application requiring solids, FOG, or BOD/COD reduction

Why choose an FRC DAF System?

With hundreds of installations worldwide, FRC is a leader in Dissolved Air Flotation technology. Our stainless-steel DAF systems combine efficiency, low maintenance, and reliability with non-proprietary components and engineering support—delivering complete solutions that ensure compliance and reduce costs.

Dissolved Air Flotation (DAF) FAQ

Q: What does a Dissolved Air Flotation (DAF) system remove from wastewater?

A: DAF systems effectively remove Total Suspended Solids (TSS), Fats, Oils & Grease (FOG), Biological Oxygen Demand (BOD), and Chemical Oxygen Demand (COD). This makes them ideal for food processing, oil & gas, pulp & paper, and municipal wastewater treatment applications.

Q: How does a DAF system work?

A: A DAF unit generates microbubbles that attach to suspended solids and FOG. These bubbles lift contaminants to the water’s surface, where they are skimmed off as sludge. Clarified effluent exits the bottom of the tank for discharge or reuse.

Q: What industries use DAF wastewater treatment systems?

A: DAF systems are widely used in food & beverage, oil & gas, petrochemical, pulp & paper, chemical manufacturing, mining, municipal wastewater, and renewable fuels. They provide cost-effective compliance with strict discharge regulations.