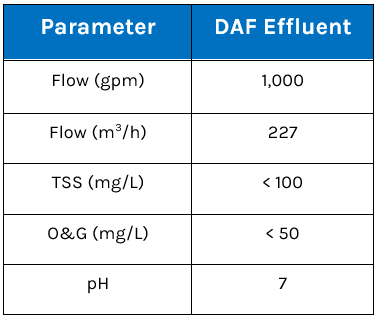

One of the largest consumer goods companies in the world and leader in foods and refreshment, health and beauty, and home care markets came to FRC to solve a problem at one of their ice cream facilities. The plant was generating wastewater with high levels of Total Suspended Solids (TSS) and Fats, Oils, and Grease (FOG) and was required to bring their wastewater into compliance levels so it could be discharged to the city.

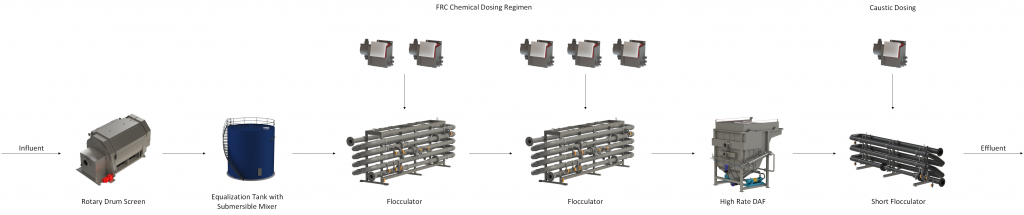

FRC’s design for most dairy applications simplifies the chemical dosing procedures while using low-cost chemicals, limits the footprint of the entire wastewater treatment system, and reduces the odors commonly associated with dairy processing operations.

Compared to conventional wastewater treatment processes, the FRC process features the following:

- Straightforward low-cost chemistry

- Less equalization needed which limits footprint

- Higher dry solids content in DAF sludge resulting in less sludge hauling

- Odor reduction

- Self-sustaining process