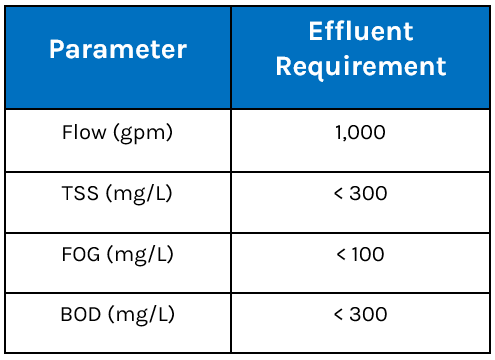

A large poultry, kill, processing, and rendering plant was generating 1.4 MGD of wastewater and needed to meet direct discharge requirements for Total Suspended Solids (TSS), Fats, Oils, and Grease (FOG), and Biological Oxygen Demand (BOD). FRC designed a pretreatment solution using two DAFs in a duty/assist configuration for peak flowrates, followed by a secondary DAF for biological treatment. The pretreatment DAF units recover proteins that the customer sells to local renderers to generate additional income of over two million dollars per year.

Poultry Kill, Process, and Rendering Application: Turnkey Solution

Design Data

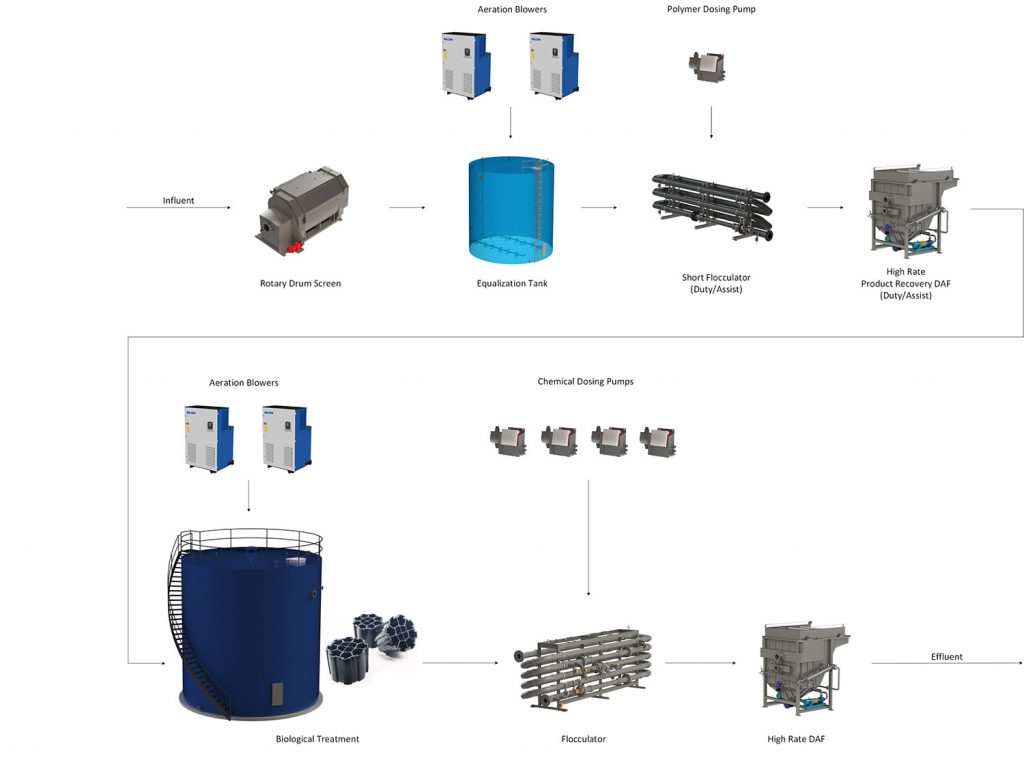

FRC Solution

- Headworks – Proper screening was done in the plant prior to Wastewater Treatment Plant

- Equalization – Homogenize wastewater for consistent wastewater characteristics. Aeration mixing is provided to prevent anoxic conditions and formation of ammonia

- Short Flocculator (Duty/Assist) – Polymer dosed to help agglomerate the fats, oils, and grease

- Primary High Rate DAF (Duty/Assist) – Floats the agglomerated solids for product recovery

- Biological Reactor – Converts dissolved BOD to biomass

- Flocculator – Chemical dosed to help separate the biomass

- Secondary High Rate DAF – Float the biomass, yielding clean effluent water