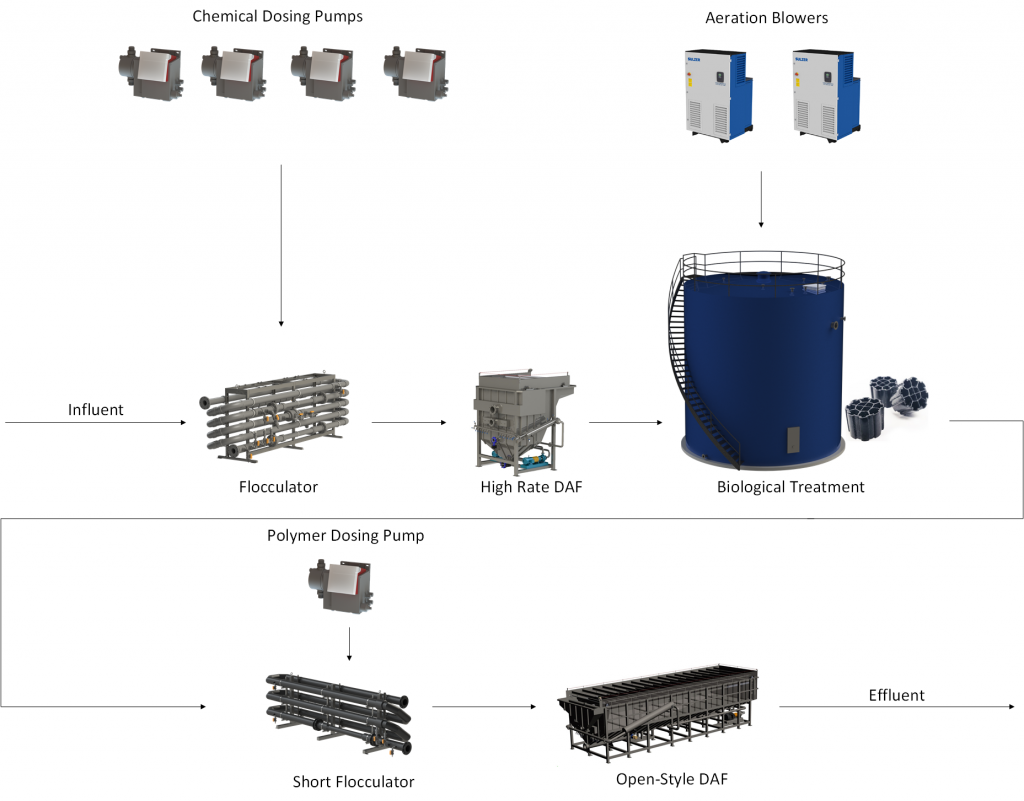

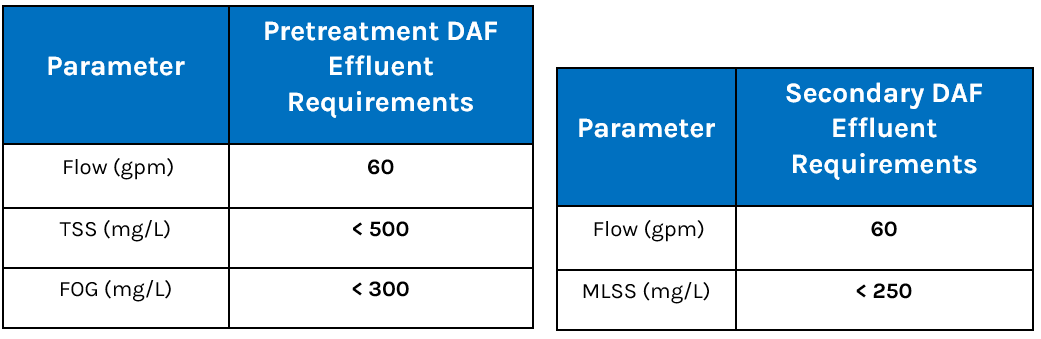

This large renewable diesel production facility was looking for a solution that could handle their high loads of Fats, Oils, and Grease (FOG), Total Suspended Solids (TSS), and Biological Oxygen Demand (BOD). FRC understands that a major factor in designing a wastewater treatment system for a renewable diesel plant is understanding how the wastewater is being generated. Cooking oils, animal fats, and inedible corn oil each present a unique challenge when it comes to wastewater management. The FRC design included a pretreatment DAF to remove the oils, grease, and gums from the wastewater generated by the grease refining process. Secondary treatment was also provided for the removal of BOD and the resulting biosolids from the biological treatment.

Renewable Energy Application: System Solution

Design Data

FRC Solution

- Primary Flocculator – Chemicals dosed to precipitate the colloidal solids and emulsified oils

- Pretreatment DAF – Float the precipitated solids thereby removing TSS, FOG, and insoluble BOD

- Biological Treatment – Remove soluble BOD and as a result creates biosolids

- Secondary Flocculator – Short flocculator to precondition biosolids with flocculant

- Secondary DAF – Float the biosolids, yielding clean effluent water for water reuse on equipment washdowns