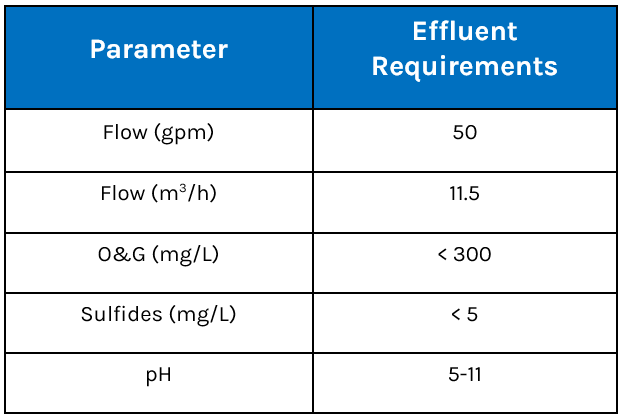

A krill oil production facility needed to quickly reduce its Oil and Grease (O&G) and sulfide levels to meet city compliance requirements. FRC mobilized a rental DAF System within a week as a temporary solution.

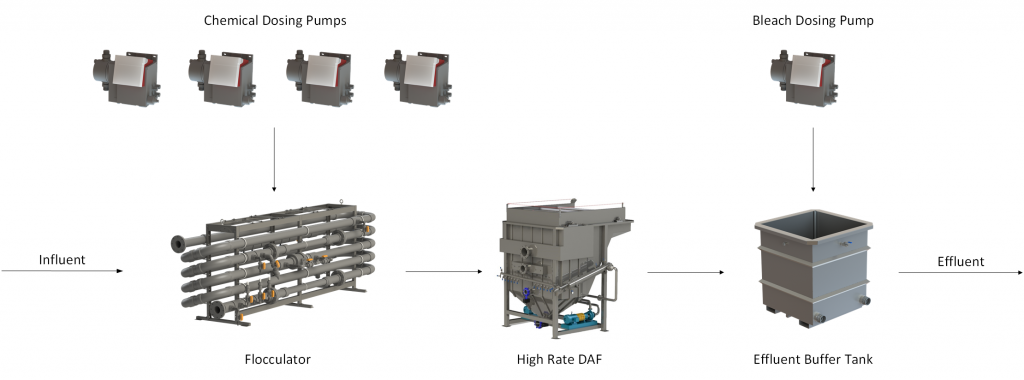

Based on the performance of the rental system and support from FRC’s engineering team, the client opted to move forward with a custom engineered permanent FRC DAF solution. The requirements included being able to move all system components with a forklift and that the installation of the equipment be complete in three days. FRC provided three pre-piped and pre-wired skids for a plug-and-play solution. This solution not only brought the client into compliance, but it is also saving them over $100,000 a year in noncompliance fees.