A leading agribusiness company with over two centuries of experience was required to bring the high Phosphorus (TP) levels in their soy processing facility back into compliance before discharge to the local water source. FRC conducted a pilot test for proof of concept of a DAF system. Per the client’s request, the pilot system treated the wastewater flow for the full production cycle. Based on the support from FRC engineers and the successful performance of the pilot system, the client implemented the FRC DAF solution.

Vegetable Oil Application: Skidded System Solution

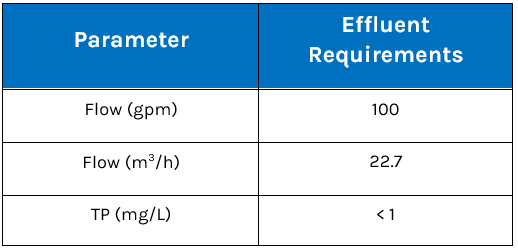

Design Data

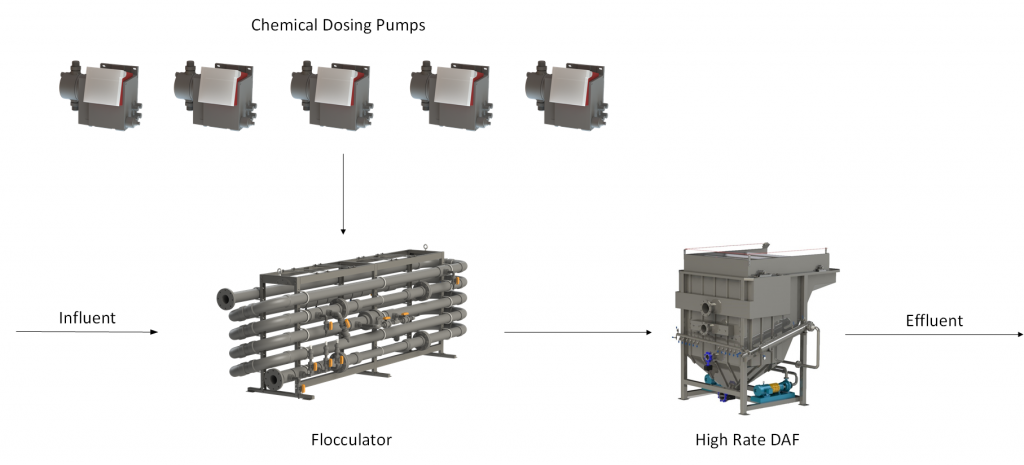

FRC Solution

- Flocculator– Chemicals dosed to precipitate the emulsified oils and colloidal solids. All chemical dosing pumps (coagulant, acid, caustic, polymer, peroxide) are installed on top of the flocculator.

- DAF Skid – Float the precipitated oils and solids thereby removing any associated TP. The E-Panel, Flocculator, and Chemical Dosing Pumps are installed on the DAF skid.