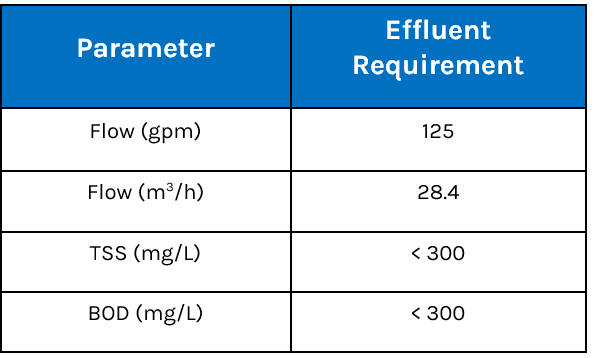

FRC designed and supplied a full turnkey mechanical and electrical installation solution for this greenfield bakery manufacturer of rebranded muffins and gourmet iced cakes. The facility had to reduce the high levels of Total Suspended Solids (TSS) and Biochemical Oxygen Demand (BOD) in their wastewater to be able to discharge to a local water source. FRC provided a complete solution to meet their compliance requirements.

Bakery Application: Turnkey Solution

Design Data

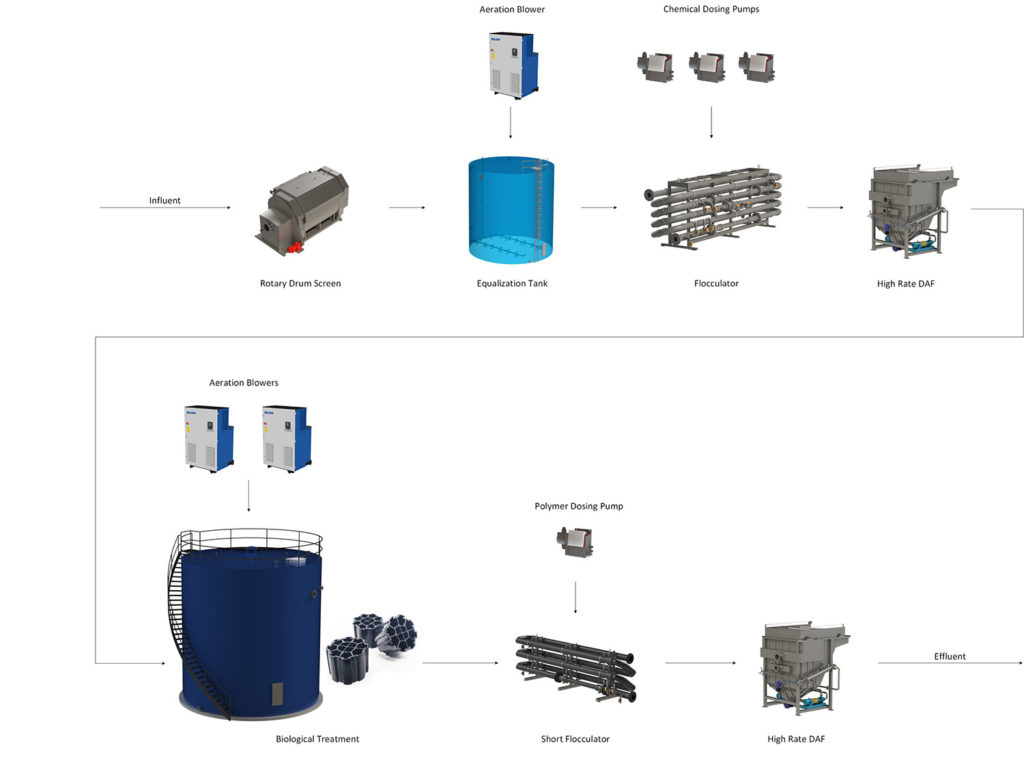

FRC Solution

- Rotary Drum Screen – Remove coarse solids such as small pieces of muffins and cakes, as well as any floating hairnets and other “garbage”.

- Equalization – Homogenize wastewater for consistent wastewater characteristics. Aeration mixing is provided to prevent anoxic conditions and formation of ammonia.

- Primary Flocculator – Chemicals dosed to precipitate the colloidal solids.

- Primary DAF – Float the precipitated solids thereby removing TSS and insoluble BOD.

- Biological Treatment – Remove soluble BOD and as a result it creates biosolids.

- Secondary Flocculator – Short flocculator to precondition biosolids with flocculant.

- Secondary DAF – Float the biosolids, yielding clean effluent water fit for discharging to the local watering source.