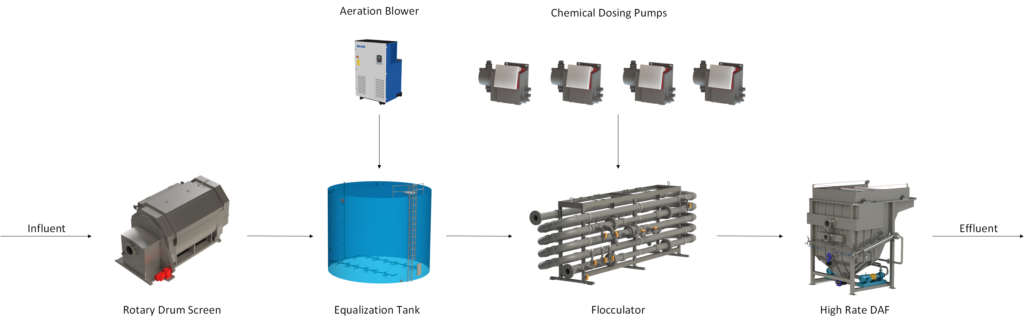

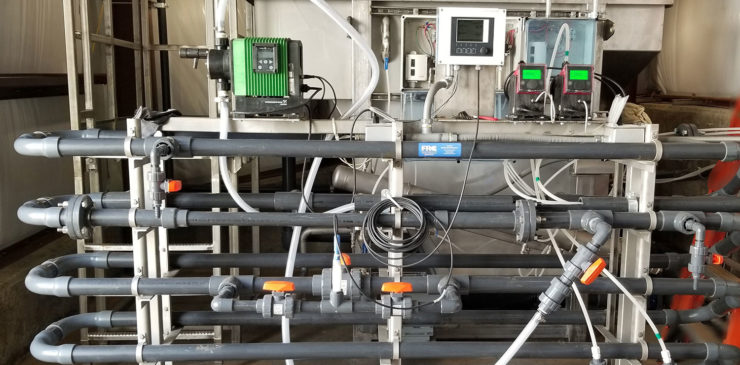

FRC was the choice of a leading copacker of sandwiches and deli spreads for a complete turnkey solution. Our scope consisted of the design of the wastewater treatment system and the mechanical and electrical installation of the new system, giving the client a one supplier solution.

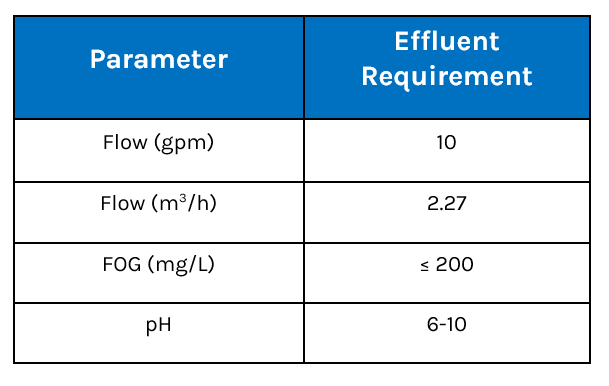

This facility produces between 12,000 to 15,000 gallons per day with high levels of Fats, Oils, and Grease (FOG) that had to be brought below 200 mg/L. FRC designed and installed the complete solution to bring them back into compliance.