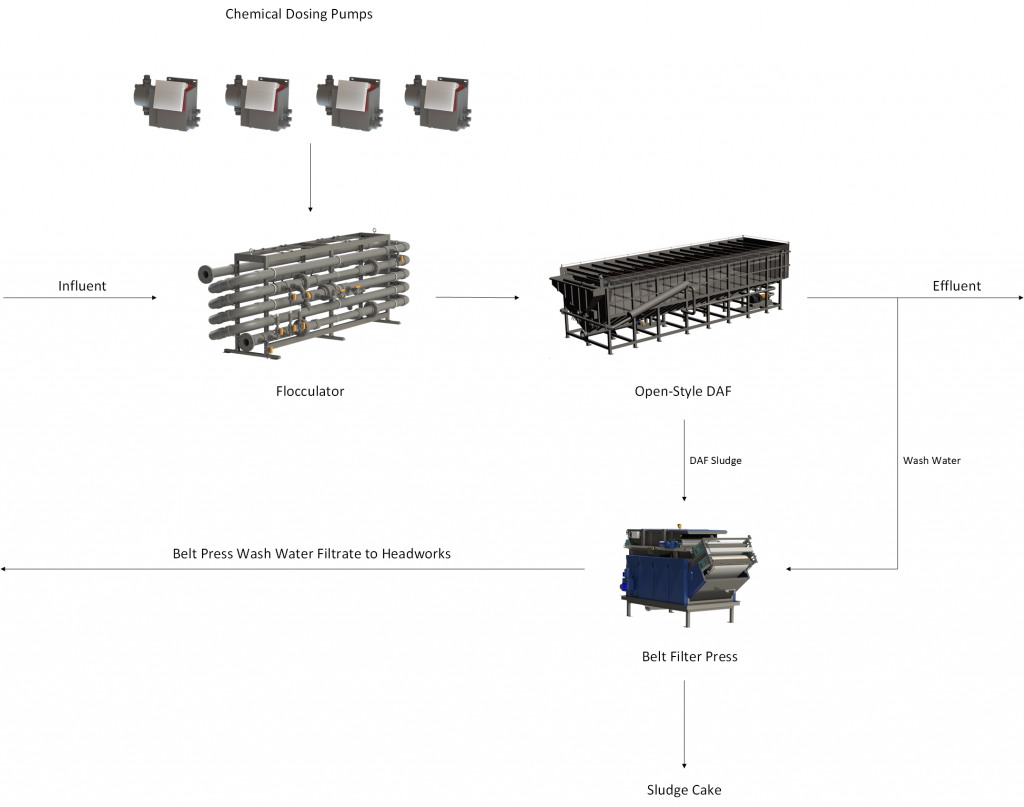

One of North America’s leading consumer products manufacturers of branded and private label household, pool, and auto care products needed an emergency wastewater treatment solution. Because of our sizable rental fleet, FRC was able to respond quickly with a rental DAF and belt press rated for the full capacity. The systems were used as a proof of concept to confirm adequate removal of Mixed Liquor Suspended Solids (MLSS) and determine cost savings on sludge dewatering. Each of the DAF, Belt Press, Flocculator, and Chemical Dosing are completely pre-piped and pre-wired on stainless steel 304 skids. The FRC design also provided additional extra cost savings by using the DAF effluent water as the wash water for the belt press. Due to excellent performance during the pilot trial, both systems were purchased as a permanent solution.

Health & Beauty Application: Skidded Solutions

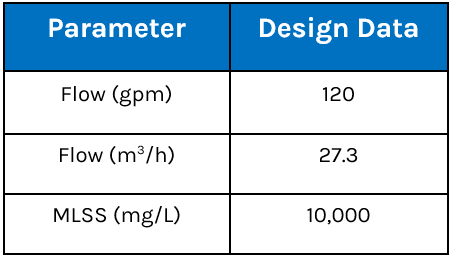

Design Data

FRC Solution

- Flocculator Skid – Chemicals dosed to precipitate the solids, includes pH transmitter

- Chemical Dosing Skid – Includes all chemical dosing pumps (coagulant, acid, caustic, polymer) and an E-Panel that interacts with the DAF Main E-Panel via an ethernet cable.

- Open-Style DAF Skid – Floats the agglomerated solids, yielding clean effluent water. The resulting effluent was used as the wash water for the Belt Press. An E-Panel (includeing PLC & HMI), duty/standby recycle pumps, and AOD sludge pump were pre-installed on this skid.

- Belt Filter Press Skid – Increase dry solids content of the DAF sludge, reducing hauling costs. The sludge feed pump, polymer dosing system, wash water pump and bag filter, and E-Panel (includes PLC & HMI) to control the belt press system.